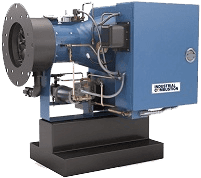

M – Series

M series burners are designed for a wide range of applications such as boilers, heaters, furnaces, kilns and dryers. The M series offers natural gas, propane gas, air atomized #2-6 oil and combination gas/oil fuel options at capacities from 1,400,000 to 10,500,000 MBTU/Hour. Full modulation and cam trim adjustment provides optimum performance to meet load demand.

Features Include:

- Gas, light and heavy oil fuels

- Low-pressure air atomizing system on oil with rotary vane compressor

- Piston-type positive displacement oil metering pump

- Cam trim with 14-point adjustment range for consistent air/fuel ratios on models M34-63

- Nozzle line electric heater standard on medium to heavy oil burners

- Gas manifold on oil burners standard for easy upgrade to combination units

- Hinged combustion head for easy access and maintenance

- Backward-curved impeller provides adequate combustion air for various furnace pressures

- Refractory combustion cone

- Full modulation

- UL & cUL listed

Capacities and Specifications

Notes:

Lower gas supply pressure configurations available for New York City requirements

- Firing rates based on altitudes to 2000ft. above sea level.

* For firing rates at higher altitudes, consult factory. - Gas input based on natural gas at 1,000 Btu/cu.ft. and 0.60 gravity

- Oil input based on 140,000 Btu/gal. on M, 145,000 Btu/gal. on MM and 150,000 Btu/gal. on ME series.

- Boiler overall efficiency of 80% estimated.

* Industrial Combustion does not guarantee overall boiler efficiency. - Gas pressure based on zero furnace pressure.

* For total pressure at manifold, add furnace pressure. - Impeller and motor HP is based on altitude up to 2,000 ft. above sea level, and up to 1.5″ W.C. furnace pressure.

* For higher altitude or 50 Hz applications, consult factory.