Engineered Combustion Systems

The Johnson Advantage

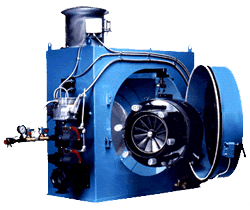

- Sub 9 ppm NOx compliance out-of-the-box

- Fuel efficient combustion with optimal low NOx

- Swing-open housing for easy maintenance

- Multiple fuel firing capability

- Proven reliable construction

Specifications

- Fuels: Gas, No. 2-6 oil

- BoilerCapacity: up to 200 Million Btu/hr

- Applications: Watertube boilers; furnaces

About

Johnson Enginered burners are designed to provide efficient and stable combustion on natural gas, LPG, or No. 2 to 6 oil with lower stack emissions.

The windbox-style systems are ideal for large capacity boilers, for which “packaged designs” are not as adaptable. Remote fan windbox systems are designed for boilers that present challenging retrofit situations, such as when mounting space is limited.

Single burner arrangements fire gas and oil up to 1,200 Boiler HP. Dual or twin-fired burners are designed for larger capacity watertube boilers. Flexible design and fabrication allow for custom engineering of a combustion system that best suits the application, taking into account the boiler type, mounting dimensions, and performance requirements.

A variable speed blower (VSB) is optimal equipment, which provides sustantial electrical cost savings over other burner designs. Selection of the most advanced parallel-positioning combustion control system ensures optimum combustion performance and efficiency.