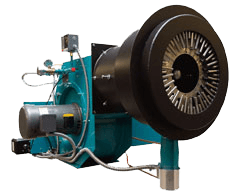

JBE(X) Series Burners

Best-In-Class Burner for Total Energy Savings

Webster’s JBE(X) boiler burner is a high efficiency, low excess air burner that incorporates a unique high swirl firing head to improve commercial boiler combustion efficiency. Perfect for hospitals, schools and universities, which are particularly cost sensitive because of tight operating budgets, the JBE(X) achieves boiler horsepower ratings in the 200 to 1,750 HP range using less fuel and electricity than conventional burners. The JBE(X)’s lower horsepower blower motor can result in significant total energy savings, depending on the boiler, burner size and operating conditions.

How It Works

Webster has combined their unique high swirl firing head technology with a highly efficient in-line combustion air fan to provide improved mixing of the fuel and air, and lower motor horsepower requirements. This combination allows the JBE series burners to operate with low excess air across a large operating range. Less excess air means high fuel efficiency, and high efficiency combined with high turndown means very low heat loss in your boiler that can result from cycling when a burner is stopping and starting. The end result is that the new Webster JBE will provide fast payback and the best possible return on your burner investment. Contact your Webster representative today so they can show you how much you can save by replacing your burner with a new Webster JBE!

To see how much total energy savings you can achieve annually by using a Webster JBE(X) burner, use this simple calculator to input your data:

Efficiency Comparison Calculator

“Please Provide This Form Embed Code”

Even More Energy Savings

When combined with Webster’s patented Temp-A-Trim™, the JBE(X) burner will maintain even lower excess air levels as operating conditions change, saving fuel and electricity and lowering maintenance costs. The JBE(X) is available for Scotch-Marine, firetube, watertube, flextube, firebox, and other heaters and vessel types.

Downloads

JBE and JBE(X) Features

- Excellent flame stability for reliable low NOx performance

- Low excess air for extremely efficient combustion

- Low Motor HP requirements and highly efficient combustion air fans to optimize electrical efficiency and provide a fast payback

High turndown rates

- Up to 12 to 1 on Gas firing

- Up to 10 to 1 on oil firing

- High turbulence combustion for better fuel mixing

- Fire multiple fuels

- Natural, LP or Digester gas

- No. 2 through No. 6 Oils

- Configurable blower housing to match application requirements

- Field-proven ignition system with an extremely stable pilot

- IFGR system with a shutoff valve in the flue gas recirculation duct to prevent fuel gas from re-entering the burner during the purge cycle

- Easy access to firing head, fan and FGR duct for maintenance

- Improved air damper with adjustable opening speeds for better turndown

- UL/cUL approved up to JBE(X)9-400M for Natural Gas and No. 2 Oil applications

- Integral combustion air fan and motor are housed in a single assembly for easy removal and inspection

- Fire all types of boilers: Scotch-Marine Firetube, Watertube, Flextube, Firebox, as well as heaters and other vessels

- Options for both pressure and air atomized oil systems