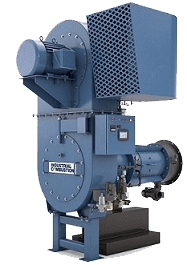

XL/LNXL – Series

The XL series is offered in two standard configurations, vertical and horizontal. Vertical configurations support capacities ranging from 37.8 to 63.0 MMBTU, and horizontal configurations support capacities from 67.2 to 92.4 MMBTU. The standard and low-NOx vertical and horizontal configurations are capable of burning natural gas, propane gas, air-atomized #2 oil, as well as combination gas/#2 oil. Full modulation operation is standard, and a parallel positioning system is required for burner management and combustion control.

Features Include:

- Available to less than 30 ppm Nox (LNXL)

- 1,800/3,600 rpm Combustion fan motor horsepower is based on Nox and capacity requirement

- Air-atomizing, low-pressure oil nozzle (steam atomization optional)

- V-port oil flow control valve is used for maximum capacity and precise oil flow control

- Parallel positioning required for optimal control throughout the firing range

- Hinged rear door and access panels for easy access to internal components

- Gas manifold on oil burners standard for easy upgrade to combination units

- Combustion air fan efficient airfoil blade design smoothly lifts airflow over the entire blade, resulting in less motor horsepower requirementand significatn noise reduction when compared to standard forced-draft fans

- #2 Oil capability for backup fuel (LNXL)

Capacities and Specifications

XL Series

| Burner Size | 378 | 420 | 462 | 504 | 546 | 588 | 630 | 672 | 756 | 840 | 924 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Frame Size | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 3 |

| Gas Input (Mbtu/hr) | 37,800 | 42,000 | 46,200 | 50,400 | 54,600 | 58,800 | 63,000 | 67,200 | 75,600 | 84,000 | 92,400 |

| Oil Input (U.S. gph) | 270 | 300 | 330 | 360 | 390 | 420 | 450 | 480 | 540 | 600 | 660 |

| Boiler Horsepower | 900 | 1,000 | 1,100 | 1,200 | 1,300 | 1,400 | 1,500 | 1,600 | 1,800 | 2,000 | 2,200 |

| Blower Motor Horsepower | 30 | 40 | 50 | 60 | 75 | 75 | 75 | 100 | 100 | 100 | 100 |

| Separate Compressor Motor HP | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Furnace Pressure (“w.c.) | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Standard Gas Train Size Pipe Size (in.) | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Gas Pressure Required (PSI) | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| Shipping Weight (lbs) | 8,000 | 8,000 | 8,000 | 9,000 | 9,000 | 10,000 | 10,000 | 12,000 | 12,000 | 12,000 | 12,000 |

LNXL – Series

| Burner Size | 378 | 420 | 462 | 504 | 546 | 588 | 630 | 672 | 756 | 840 | 924 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Frame Size | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 3 |

| Gas Input (Mbtu/hr) | 37,800 | 42,000 | 46,200 | 50,400 | 54,600 | 58,800 | 63,000 | 67,200 | 75,600 | 84,000 | 92,400 |

| Oil Input (U.S. gph) | 270 | 300 | 330 | 360 | 390 | 420 | 450 | 480 | 540 | 600 | 660 |

| Boiler Horsepower | 900 | 1,000 | 1,100 | 1,200 | 1,300 | 1,400 | 1,500 | 1,600 | 1,800 | 2,000 | 2,200 |

| Blower Motor Horsepower | 30 | 40 | 50 | 60 | 75 | 75 | 75 | 100 | 100 | 100 | 100 |

| Separate Compressor Motor HP | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Furnace Pressure (“w.c.) | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Standard Gas Train Size Pipe Size (in.) | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Gas Pressure Required (PSI) | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| Shipping Weight (lbs) | 8,000 | 8,000 | 8,000 | 9,000 | 9,000 | 10,000 | 10,000 | 12,000 | 12,000 | 12,000 | 12,000 |

Model

Gas Based:

|

Oil Based:

|

Gas/Oil Based:

|

Notes:

- Firing rates based on 60 cycle and an altitude up to 2,000 ft. above sea level.

* For firing rates at higher altitudes, consult factory. - Oil input based on No. 2 oil @ 140,000 Btu/gal

- Gas input based on Natural Gas @ 1,000 Btu/cu.ft. and 0.60 specific gravity

- Boiler overall efficiency of 80% estimated

- Shipping weight is only an estimate